Author: ChangMing

Featured Nickel Alloy Supplied by MetalsPiping

Recently, Metals-Piping has supplied nickel alloy materials to several chemical & petrochemical projects. The piping materials includes Alloy 20 pipe fittings for sulfuric acid alkylation plant in Czech; Inconel 600 flanges supplied to a WAO system for spent caustic treatment in Qatar.

| Specification | Quantity |

|---|---|

| ASTM B729 Alloy 20 seamless pipes, 6″ SCH40, length=6m | 16 pieces |

| ASTM B366 Alloy 20 fittings(WP20CB), 6″ elbows L/R 90° SCH40 | 6 pieces |

| Alloy 20 weld neck flange, 6“ SCH40, 150# | 8 pieces |

| Alloy 20 lap joint stub ends, 4″ long pattern, ASME B16.9. | 7 pieces |

ASTM B564 UNS N06600 (Inconel 600) welding neck flanges 12″ SCH120 Class 900, 6 pieces.

Metals Piping – Our Division’s New Website

Metalsin Tech has released its new website for the piping division: www.metalspiping.com Metals-Piping Division is the supplier of piping materials (flange, fittings, pipes, tubes, fasteners, pressure vessel, etc) manufactured from nickel & nickel alloys, Cr-Mo alloy steels and other alloy steels, carbon and stainless steels.

Any inquiry, please feel free to contact us.

sales@metalspiping.com

Flange Bolting for Class 2500 ASME B16.5 Flanges

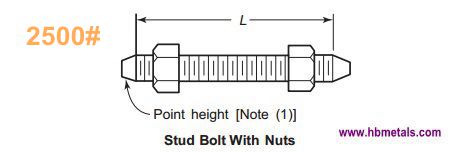

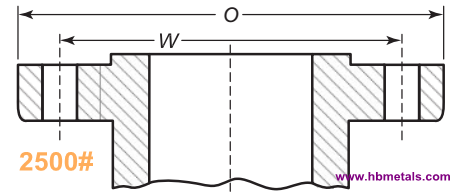

1. Technical drawings of flange bolting for Class 2500 ASME B16.5 flanges.

2. Dimensions of flange bolting for Class 2500 ASME B16.5 flanges.

| NPS | O inch mm | W inch mm | m inch | n | d inch | L1 inch mm | L2 inch mm | L3 inch mm |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 5.25 135 | 3.50 88.9 | 7/8 | 4 | 3/4 | 4.75 120 | 4.50 115 | 4.75 120 |

| 3/4 | 5.50 140 | 3.75 95.2 | 7/8 | 4 | 3/4 | 5.00 125 | 4.75 120 | 5.00 125 |

| 1 | 6.25 160 | 4.25 108.0 | 1 | 4 | 7/8 | 5.50 140 | 5.25 135 | 5.50 140 |

| 1 1/4 | 7.25 185 | 5.12 130.2 | 1 1/8 | 4 | 1 | 6.00 150 | 5.75 145 | 6.00 150 |

| 1 1/2 | 8.00 205 | 5.75 146.0 | 1 1/4 | 4 | 1 1/8 | 6.75 170 | 6.50 165 | 6.75 170 |

| 2 | 9.25 235 | 6.75 171.4 | 1 1/8 | 8 | 1 | 7.00 180 | 6.75 170 | 7.00 180 |

| 2 1/2 | 10.50 265 | 7.75 196.8 | 1 1/4 | 8 | 1 1/8 | 7.75 195 | 7.50 190 | 8.00 205 |

| 3 | 12.00 305 | 9.00 228.6 | 1 3/8 | 8 | 1 1/4 | 8.75 220 | 8.50 215 | 9.00 230 |

| 4 | 14.00 355 | 10.75 273.0 | 1 5/8 | 8 | 1 1/2 | 10.00 255 | 9.75 250 | 10.25 260 |

| 5 | 16.50 420 | 12.75 323.8 | 1 7/8 | 8 | 1 3/4 | 11.75 300 | 11.50 290 | 12.25 310 |

| 6 | 19.00 485 | 14.50 368.3 | 2 1/8 | 8 | 2 | 13.50 345 | 13.25 335 | 14.00 355 |

| 8 | 21.75 550 | 17.25 438.2 | 2 1/8 | 12 | 2 | 15.00 380 | 14.75 375 | 15.50 395 |

| 10 | 26.50 675 | 21.25 539.8 | 2 5/8 | 12 | 2 1/2 | 19.25 490 | 19.00 485 | 20.00 510 |

| 12 | 30.00 760 | 24.38 619.1 | 2 7/8 | 12 | 2 3/4 | 21.25 540 | 21.00 535 | 22.00 560 |

1. For the denotation of dimensions “NPS, O, W, m, n, d, L1, L2, L3”, please refer to that of flange bolting for Class 1500. The length of the stud bolt doesn’t include the height of the points.

2. The bolting of ASME B16.5 class 2500 flanges can be furnished as stud bolts with nuts. Stud bolts can be used for flanges with either raised face or ring joint face. All dimensions are provided in mm and inch units.

| ASME B16.5 Flange Bolting Specification by Classes | ||||||

|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

Flange Bolting for Class 1500 ASME B16.5 Flanges

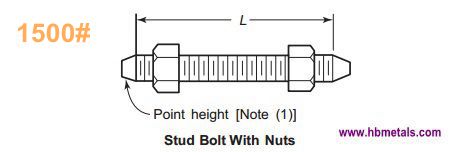

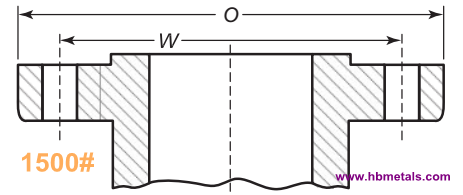

1. Technical drawings of flange bolting for Class 1500 ASME B16.5 flanges.

2. Dimensions of flange bolting for Class 1500 ASME B16.5 flanges.

| NPS | O inch mm | W inch mm | m inch | n | d inch | L1 inch mm | L2 inch mm | L3 inch mm |

|---|---|---|---|---|---|---|---|---|

| 1/2" | 4.75 120 | 3.25 82.6 | 7/8 | 4 | 3/4 | 4.25 110 | 4.00 100 | 4.25 110 |

| 3/4" | 5.12 130 | 3.50 88.9 | 7/8 | 4 | 3/4 | 4.50 115 | 4.25 110 | 4.50 115 |

| 1" | 5.88 150 | 4.00 101.6 | 1 | 4 | 7/8 | 5.00 125 | 4.75 120 | 5.00 125 |

| 1 1/4" | 6.25 160 | 4.38 111.1 | 1 | 4 | 7/8 | 5.00 125 | 4.75 120 | 5.00 125 |

| 1 1/2" | 7.00 180 | 4.88 123.8 | 1 1/8 | 4 | 1 | 5.50 140 | 5.25 135 | 5.50 140 |

| 2" | 8.50 215 | 6.50 165.1 | 1 | 8 | 7/8 | 5.75 145 | 5.50 140 | 5.75 145 |

| 2 1/2" | 9.62 245 | 7.50 190.5 | 1 1/8 | 8 | 1 | 6.25 160 | 6.00 150 | 6.25 160 |

| 3" | 10.50 265 | 8.00 203.2 | 1 1/4 | 8 | 1 1/8 | 7.00 180 | 6.75 170 | 7.00 180 |

| 4" | 12.25 310 | 9.50 241.3 | 1 3/8 | 8 | 1 1/4 | 7.75 195 | 7.50 190 | 7.75 195 |

| 5" | 14.75 375 | 11.50 292.1 | 1 5/8 | 8 | 1 1/2 | 9.75 250 | 9.50 240 | 9.75 250 |

| 6" | 15.50 395 | 12.50 317.5 | 1 1/2 | 12 | 1 3/8 | 10.25 260 | 10.00 255 | 10.50 265 |

| 8" | 19.00 485 | 15.50 393.7 | 1 3/4 | 12 | 1 5/8 | 11.50 290 | 11.25 285 | 11.75 300 |

| 10" | 23.00 585 | 19.00 482.6 | 2 | 12 | 1 7/8 | 13.25 335 | 13.00 330 | 13.50 345 |

| 12" | 26.50 675 | 22.50 571.5 | 2 1/8 | 16 | 2 | 14.75 375 | 14.50 370 | 15.25 385 |

| 14" | 29.50 750 | 25.00 635.0 | 2 3/8 | 16 | 2 1/4 | 16.00 405 | 15.75 400 | 16.75 425 |

| 16" | 32.50 825 | 27.75 704.8 | 3 5/8 | 16 | 2 1/2 | 17.50 445 | 17.25 440 | 18.50 470 |

| 18" | 36.00 915 | 30.50 774.7 | 2 7/8 | 16 | 2 3/4 | 19.50 495 | 19.25 490 | 20.75 525 |

| 20" | 38.75 985 | 32.75 831.8 | 3 1/8 | 16 | 3 | 21.25 540 | 21.00 535 | 22.25 565 |

| 24" | 46.00 1170 | 39.00 990.6 | 3 5/8 | 16 | 3 1/2 | 24.25 615 | 24.00 610 | 25.50 650 |

1. For the denotation of dimensions “NPS, O, W, m, n, d, L1, L2, L3”, please refer to that of flange bolting for Class 900. The length of the stud bolt doesn’t include the height of the points.

2. The bolting of ASME B16.5 class 1500 flanges can be furnished as stud bolts with nuts. Stud bolts can be used for flanges with either raised face or ring joint face. All dimensions are provided in mm and inch units.

| ASME B16.5 Flange Bolting Specification by Classes | ||||||

|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

EN 10216-4 P255QL Seamless Steel Tube / Pipe

EN 10216-4 is the standard specification for seamless steel tubes for pressure purposes – Technical delivery conditions – Part 4: Non-alloy and alloy steel tubes with specified low temperature properties. P255QL, with a steel number of 1.0452, is one of the non-alloy quality steel grades designated by EN 10216-4. The EN 10216-4 P255QL seamless tubes are often used in services with a minimum temperature of -46°C.

Chemical composition of EN 10216-4 P255QL / 1.0452

| Element | Content by mass, % |

|---|---|

| Carbon (C) | ≤0.17 |

| Silicon (Si) | ≤0.35 |

| Manganese (Mn) | 0.40~1.20 |

| Phosphorous (P) | ≤0.025 |

| Sulfur (S) | ≤0.020 |

| Chromium (Cr) | ≤0.30 |

| Nickel (Ni) | ≤0.30 |

| Molybdenum (Mo) | ≤0.08 |

| Aluminium (Al) | ≥0.020 |

| Copper (Cu) | ≤0.30 |

| Niobium (Nb) | ≤0.010 |

| Titanium (Ti) | ≤0.040 |

| Vanadium (V) | ≤0.02 |

Mechanical properties of EN 10216-4 P255QL / 1.0452

| Steel Name | Steel Number | Yield Strength, MPa | Tensile Strength, MPa | Elongation A Longitudinal, % | Elongation B Transverse, % |

|---|---|---|---|---|---|

| P255QL | 1.0452 | ≥255 | 360~490 | ≥23 | ≥21 |

Heat treatment conditions

For low-temperature purpose, EN 10216-4 P255QL shall be fully killed. The capital letter “P” stands for pressure purposes; “255” indicates the minimum yield strength of 255 MPa; “Q” indicates the heat treatment as quenching and tempering; “L” indicates the use for low-temperature purposes.

Usually the seamless tube or pipe of grade P255QL shall be quenched and tempered. The quenching temperature(hardening temperature) shall be at 890°C to 930°C while tempering temperature is ranging from 600°C to 680°C.

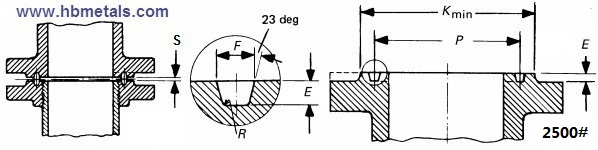

Ring Joint Facings for Class 2500 ASME B16.5 Flanges

1. Technical drawings of ring joint facings for Class 2500 ASME B16.5 Flanges.

2. Dimensions of ring joint facings for Class 2500 Flange Joints and Groove.

| NPS | Groove Number | P inch mm | E inch mm | F inch mm | R inch mm | K inch mm | S inch mm |

|---|---|---|---|---|---|---|---|

| 1/2" | 13 | 1.688 42.88 | 0.250 6.35 | 0.344 8.74 | 0.03 0.8 | 2.56 65.0 | 0.16 4 |

| 3/4" | 16 | 2.000 50.80 | 0.250 6.35 | 0.344 8.74 | 0.03 0.8 | 2.88 73.0 | 0.16 4 |

| 1" | 18 | 2.375 60.33 | 0.250 6.35 | 0.344 8.74 | 0.03 0.8 | 3.25 82.5 | 0.16 4 |

| 1 1/4 | 21 | 2.844 72.23 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 4.00 102 | 0.12 3 |

| 1 1/2 | 23 | 3.250 82.55 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 4.50 114 | 0.12 3 |

| 2 | 26 | 4.000 101.60 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 5.25 133 | 0.12 3 |

| 2 1/2 | 28 | 4.375 111.13 | 0.375 9.53 | 0.531 13.49 | 0.03 0.8 | 5.88 149 | 0.12 3 |

| 3 | 32 | 5.000 127.00 | 0.375 9.53 | 0.531 13.49 | 0.03 0.8 | 6.62 168 | 0.12 3 |

| 4 | 38 | 6.188 157.18 | 0.438 11.13 | 0.656 16.66 | 0.06 1.5 | 8.00 203 | 0.19 4 |

| 5 | 42 | 7.500 190.50 | 0.500 12.70 | 0.781 19.84 | 0.06 1.5 | 9.50 241 | 0.19 4 |

| 6 | 47 | 9.000 228.60 | 0.500 12.70 | 0.781 19.84 | 0.06 1.5 | 11.00 279 | 0.19 4 |

| 8 | 51 | 11.000 279.40 | 0.562 14.27 | 0.906 23.01 | 0.06 1.5 | 13.38 340 | 0.19 5 |

| 10 | 55 | 13.500 342.90 | 0.688 17.48 | 1.188 30.18 | 0.09 2.4 | 16.75 425 | 0.25 6 |

| 12 | 60 | 16.000 406.40 | 0.688 17.48 | 1.312 33.32 | 0.09 2.4 | 19.50 495 | 0.31 8 |

1.For denotation of ” NPS, P, E, F, R, K, S “, please refer to ring joint facings for Class 300 ASME B16.5 flanges.

2. All dimensions are provided in mm and inch unit. The depth of the groove, E, shall be furnished with the same dimension as the height of the raised portion. The groove number of ring joint facings for class 2500 shall match the type R ring gaskets manufactured to ASME B16.20.

| Ring Joint Facings for ASME B16.5 Flanges Classified by Classes | ||||||

|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

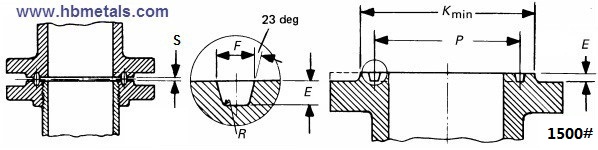

Ring Joint Facings for Class 1500 ASME B16.5 Flanges

1. Technical drawings of ring joint facings for Class 1500 ASME B16.5 Flanges.

2. Dimensions of ring joint facings for Class 1500 Flange Joints and Groove.

| NPS | Groove Number | P inch mm | E inch mm | F inch mm | R inch mm | K inch mm | S inch mm |

|---|---|---|---|---|---|---|---|

| 1/2" | 12 | 1.562 39.67 | 0.250 6.35 | 0.344 8.74 | 0.03 0.8 | 2.38 60.5 | 0.16 4 |

| 3/4" | 14 | 1.750 44.45 | 0.250 6.35 | 0.344 8.74 | 0.03 0.8 | 2.62 66.5 | 0.16 4 |

| 1" | 16 | 2.000 50.80 | 0.250 6.35 | 0.344 8.74 | 0.03 0.8 | 2.81 71.5 | 0.16 4 |

| 1 1/4" | 18 | 2.375 60.33 | 0.250 6.35 | 0.344 8.74 | 0.03 0.8 | 3.19 81.0 | 0.16 4 |

| 1 1/2" | 20 | 2.688 68.27 | 0.250 6.35 | 0.344 8.74 | 0.03 0.8 | 3.62 92.0 | 0.16 4 |

| 2" | 24 | 3.750 95.25 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 4.88 124 | 0.12 3 |

| 2 1/2" | 27 | 4.250 107.95 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 5.38 137 | 0.12 3 |

| 3" | 35 | 5.375 136.53 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 6.62 168 | 0.12 3 |

| 4" | 39 | 6.375 161.93 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 7.62 194 | 0.12 3 |

| 5" | 44 | 7.625 193.68 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 9.00 229 | 0.12 3 |

| 6" | 46 | 8.312 228.60 | 0.375 9.53 | 0.531 13.49 | 0.06 1.5 | 9.75 248 | 0.12 3 |

| 8" | 50 | 10.625 269.88 | 0.438 11.13 | 0.656 16.66 | 0.06 1.5 | 12.50 318 | 0.16 4 |

| 10" | 54 | 12.750 323.85 | 0.438 11.13 | 0.656 16.66 | 0.06 1.5 | 14.62 371 | 0.16 4 |

| 12" | 58 | 15.000 381.00 | 0.562 14.27 | 0.906 23.01 | 0.06 1.5 | 17.25 438 | 0.19 5 |

| 14" | 63 | 16.500 419.10 | 0.625 15.88 | 1.062 26.97 | 0.09 2.4 | 19.25 489 | 0.22 6 |

| 16" | 67 | 18.500 469.90 | 0.688 17.48 | 1.188 30.18 | 0.09 2.4 | 21.50 546 | 0.31 8 |

| 18" | 71 | 21.000 533.40 | 0.688 17.48 | 1.188 30.18 | 0.09 2.4 | 24.12 613 | 0.31 8 |

| 20" | 75 | 23.000 584.00 | 0.688 17.48 | 1.312 33.32 | 0.09 2.4 | 26.50 673 | 0.38 10 |

| 24" | 79 | 27.250 692.15 | 0.812 20.62 | 1.438 36.53 | 0.09 2.4 | 31.25 794 | 0.44 11 |

1.For denotation of ” NPS, P, E, F, R, K, S “, please refer to ring joint facings for Class 300 ASME B16.5 flanges.

2. All dimensions are provided in mm and inch unit. The depth of the groove, E, shall be furnished with the same dimension as the height of the raised portion. The groove number of ring joint facings for class 1500 shall match the type R ring gaskets manufactured to ASME B16.20.

| Ring Joint Facings for ASME B16.5 Flanges Classified by Classes | ||||||

|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

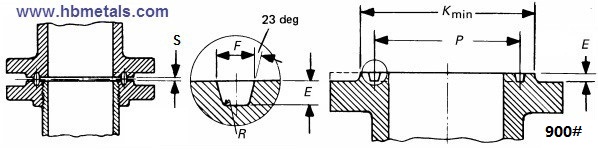

Ring Joint Facings for Class 900 ASME B16.5 Flanges

1. Technical drawings of ring joint facings for Class 900 ASME B16.5 Flanges.

2. Dimensions of ring joint facings for Class 900 Flange Joints and Groove.

| NPS | Groove Number | P inch mm | E inch mm | F inch mm | R inch mm | K inch mm | S inch mm |

|---|---|---|---|---|---|---|---|

| 3" | 31 | 4.875 123.83 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 6.12 156 | 0.16 4 |

| 4" | 37 | 5.875 149.23 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 7.12 181 | 0.16 4 |

| 5" | 41 | 7.125 180.98 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 8.50 216 | 0.16 4 |

| 6" | 45 | 8.312 211.12 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 9.50 241 | 0.16 4 |

| 8" | 49 | 10.625 269.88 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 12.12 248 | 0.16 4 |

| 10" | 53 | 12.750 323.85 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 14.25 362 | 0.16 4 |

| 12" | 57 | 15.000 381.00 | 0.312 7.92 | 0.469 11.91 | 0.03 0.8 | 16.50 419 | 0.16 4 |

| 14" | 62 | 15.625 419.10 | 0.438 11.13 | 0.656 16.66 | 0.06 1.5 | 18.38 467 | 0.16 4 |

| 16" | 66 | 17.875 469.90 | 0.438 11.13 | 0.656 16.66 | 0.06 1.5 | 20.62 254 | 0.16 4 |

| 18" | 70 | 20.375 533.40 | 0.500 12.70 | 0.781 19.84 | 0.06 1.5 | 23.38 594 | 0.19 5 |

| 20" | 74 | 22.000 584.20 | 0.500 12.70 | 0.781 19.84 | 0.06 1.5 | 25.50 648 | 0.19 5 |

| 24" | 78 | 26.500 692.15 | 0.625 15.88 | 1.062 26.97 | 0.09 2.4 | 30.38 772 | 0.22 6 |

1.For denotation of ” NPS, P, E, F, R, K, S “, please refer to ring joint facings for Class 300 ASME B16.5 flanges.

2. All dimensions are provided in mm and inch unit. The depth of the groove, E, shall be furnished with the same dimension as the height of the raised portion. The groove number of ring joint facings for class 900 shall match the type R ring gaskets manufactured to ASME B16.20.

| Ring Joint Facings for ASME B16.5 Flanges Classified by Classes | ||||||

|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

16Mo3 Steel Plates and Pipes for Power Plant Piping

In 25th September 2015, Hebei Metals Industrial Limited received a large order from BULMFELD, who is a German contracting company dedicating to power-station solution in Europe. The order is for a power plant project in Czech Republic. Considering the high temperature conditions, 16Mo3 / 1.5415 as well as its ASTM equivalent(ASTM A335 Gr.P1 / ASTM A204 Gr.A and Gr.B) are specifed to meet the European design code. The 16Mo3 steel plate manufactured to EN 10028-2 is required for prefabrication of the pressure vessel while 16Mo3 steel pipes(seamless) made to EN 10216-2 are required for the heat-exchanger piping.

EN 10028-2 Grade 16Mo3 Steel Plate

EN 10216-2 16Mo3 Seamless Steel Pipes DN 80 & DN 100